How can companies benefit from networked data along the entire value chain? What potential do digital technologies offer for resource conservation, process reliability and new business models in the food industry? These and other questions were at the centre of this year's focus day in the smartFoodTechnologyOWL partnership. In addition to exciting lectures, workshops and the presentation of new laboratory areas on the Innovation Campus Lemgo, the event offered numerous opportunities for dialogue and networking.

inIT participated in this year's focus day with a talk by Philip Sehr, a workshop on the Asset Administration Shell and the presentation of the FoodLifeTimeTracking demonstrator with a total of three contributions.

FoodLifeTimeTracking: Rethinking shelf life

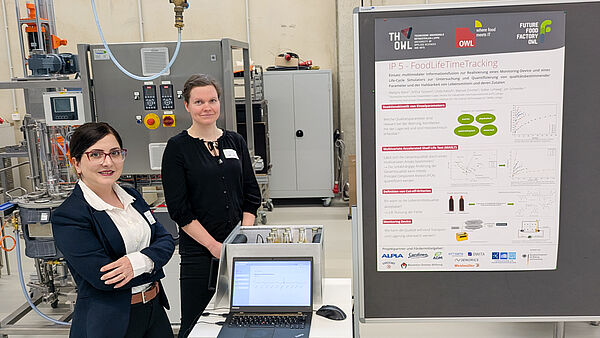

Masoumeh Darvishi, research associate in the inIT Image Processing and Pattern Recognition, Sensor and Information Fusion research group headed by Prof. Dr. Volker Lohweg, presented the demonstrator of the FoodLifeTimeTracking project, which is being carried out in close cooperation with the Institute for Life Science Technologies (ILT.NRW). She used the demonstrator to show how non-invasive sensor technology and data-based models can be used to predict the shelf life of food more accurately in the future. The aim is to implement an adaptive shelf-life prediction (Dynamic Shelf-Life, DSL) that increases product safety and improves resource efficiency along the supply chain. To this end, accelerated shelf-life tests and external measurement methods will be used to develop adaptive prediction models that can complement or replace traditional laboratory methods in the long term.

Digital product passport as a door opener for new business models

Philip Sehr, a research assistant in Prof. Dr. Henning Trsek's inIT Interconnected Automation Systems research group, gave an interesting impulse with his presentation "The Digital Product Passport as an Enabler for New Business Models - Automated Quality Management in System Catering". He explained the role of the Asset Administration Shell (AAS) as a key technology for interoperability. Using concrete scenarios, he showed how standardised data structures can be used to support the lifecycle of physical products in a transparent and efficient way - especially for small and medium-sized companies looking for a step-by-step introduction to digitalisation.

CinITo demonstrator: hands-on digitalisation

The workshop "The Asset Administration Shell as a standard for digital twins in I4.0 - Where does the information for the digital product passport come from?" at the CinITo demonstrator on the ground floor of the CIIT building provided a vivid example of the practical application of digital technologies. Organised and run jointly by research group leader Natalia Moriz, Philip Sehr and CIIT managing director Anja Moldehn, the workshop demonstrated how the concept of the digital twin can be put into practice. While a robot served participants freshly brewed coffee, Philip Sehr explained the technical basics and the benefits of digital images of real objects - particularly in terms of automated quality assurance and efficient process control.

The focus day showed how the interdisciplinary cooperation between inIT and ILT.NRW opens up new perspectives for the food production of the future. The projects presented showed how practice-oriented research along the value chain provides concrete answers to current challenges - from dynamic shelf life and digital product data to smart production.